Electronics and Optics Hardware Development Lifecycle

Opto-Electronic Intelligence

Design and Development for Opto-Electronic Hardware

- Requirements -> Test Specs -> Hardware Development

- Hardware Development

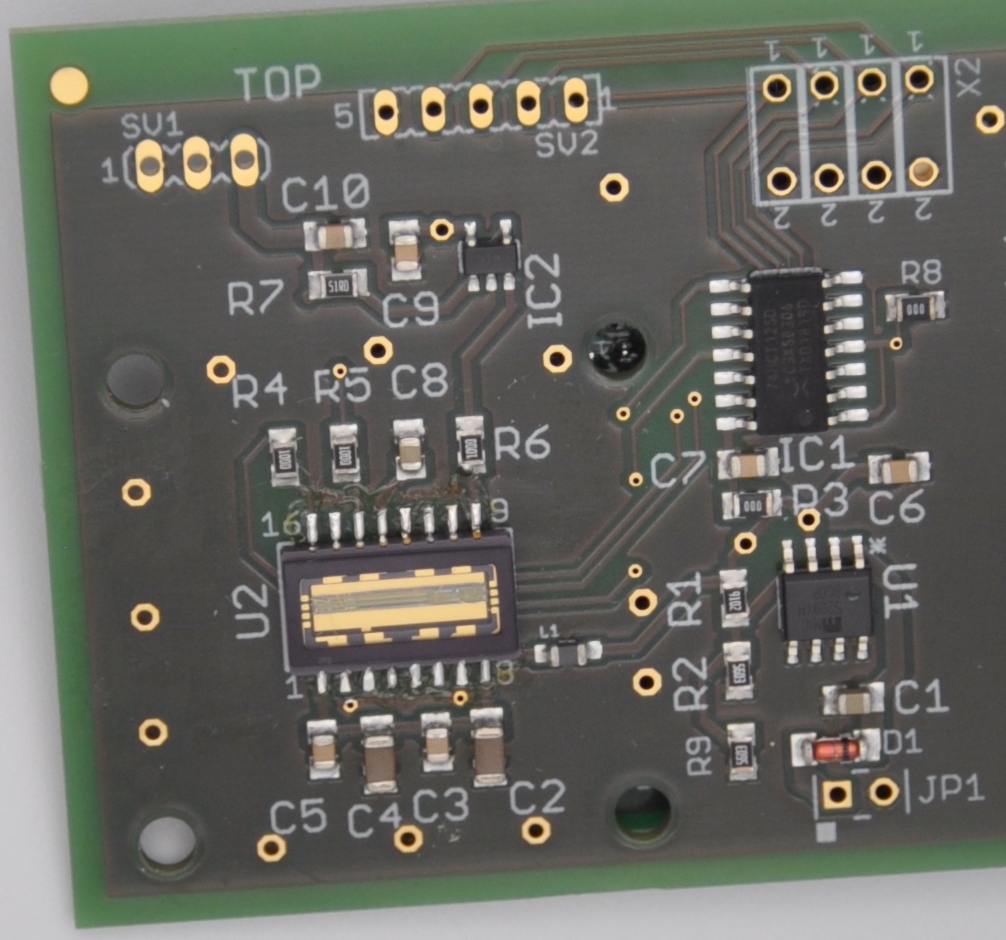

- Modularisation into testable entities

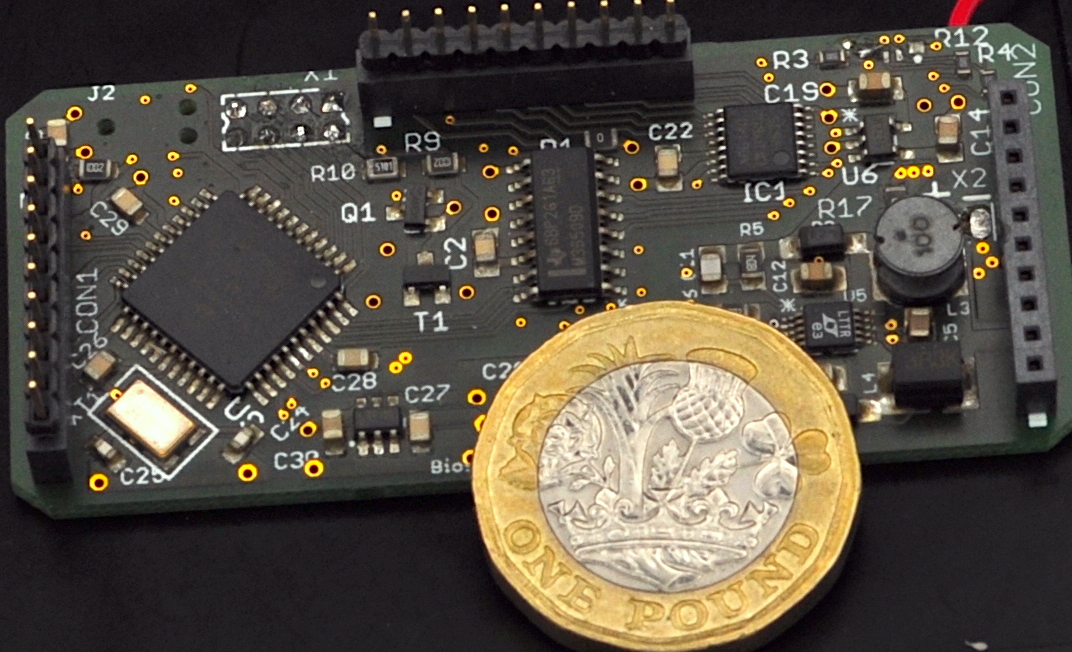

- Rapid design iteration for early prototypes

- Schematics, module PCBs

- Characterisation and testing

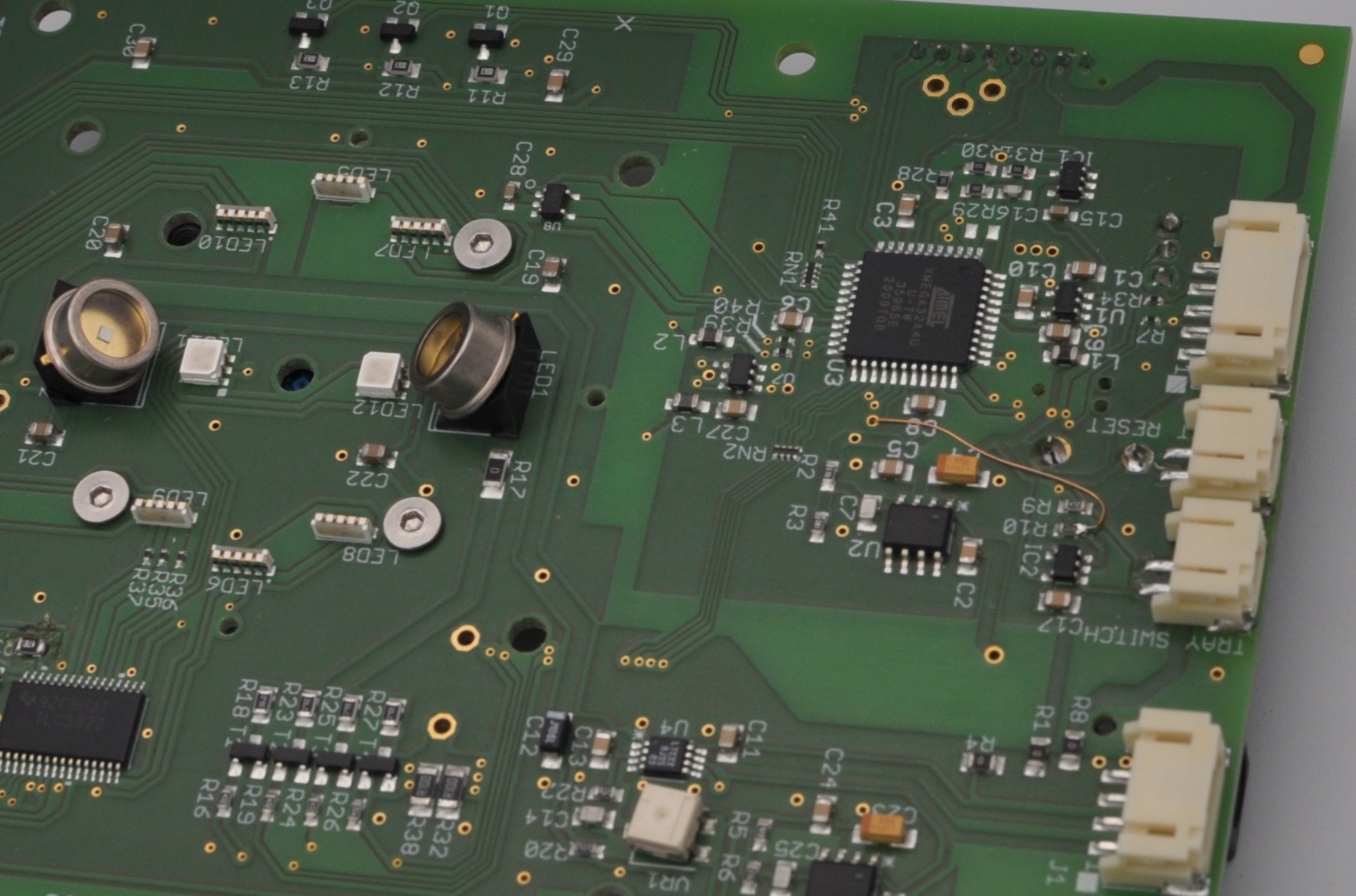

- Integration of modules to complete system

- Integrated PCB with annotated schematics

- Acceptance Testing

- Design optimisation and pre-production.

- Release PCB

- Test Driven Development for hardware

- Continuous Integration (CI) setup from start

- Everything hosted on a Git repository of your choice.

- CI on the development machine with test harnesses

- Integration testing with Python based automated testing

- Hardware-in-loop (HIL) implemented when needed

- Efficient hardware design in KiCAD1 or Eagle CAD (Autodesk)

- up to 4 layers electronics PCB

- Quick turn-around for urgent electronic prototypes by experienced hand assembly

- Suited for up to 50 surface mount and 20 through-hole components

- All boards manufactured in Europe

- Preferred suppliers:

Included Services

- Requirements and Testing Documents

- Delivery of reproducible testing environment

- Tech-transfer; no holding out on knowledge

- Bill-of-materials (BOM)

- CAD output for records

All components sourced from reputable suppliers only:

- Digikey, Farnell, RS Components or Mouser

- Hamamatsu for higher spec photonic components (photodiodes and arrays)

- Comar Optics, Edmund Optics, Thorlabs for Opto-Mechanical Components

PCBs Sourced from UK/Europe only Up to 3 PCBs can be hand-assembled for rapid-turnaround Small batch can be ordered by machine assembly with turn-around time of 3 weeks

Footnotes

KiCAD is a free and open-source EDA https://www.kicad.org/. It is used and supported by several companies and research institure including CERN https://ohwr.org/project/cern-kicad/wikis/home↩︎